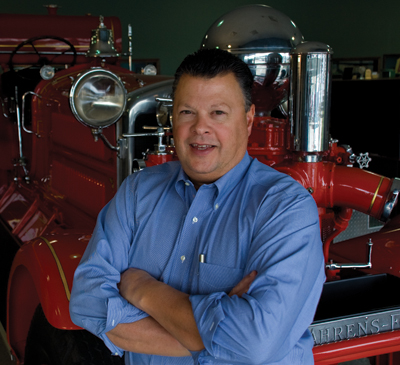

Ferrara Fire Apparatus dates to 1979 when President and CEO Chris Ferrara founded Ferrara Firefighting Equipment. At the time a pipefitter/fabricator for one of the nation's largest petrochemical refineries in Baton Rouge, Louisiana, Chris was also a volunteer firefighter at Central Volunteer Fire Department.

While he was contributing to the community by volunteering his services as a member of the local fire department, Chris soon realized and understood the many constraints placed on fire departments. Central VFD served a rural area without hydrants to adequately service their community. This created a need for a water tanker to assist in firefighting operations. The cost of a new apparatus, coupled with a virtual lack of funding, required other avenues to be explored in order to procure the apparatus.

With his knowledge of firefighting and experience in fabrication, Chris and other members of the Department decided to build their own tanker. After many hours of hard work and dedication, this group of young firemen, led by Chris, delivered the new tanker fire truck to their department in Central. And perhaps most importantly, they accomplished this while saving the community thousands of dollars.

The tanker project was a success and it inspired a career change for Chris. He soon founded a firefighting equipment and supply distributorship, initially operating out of his home. Ferrara Firefighting Equipment represented many of the industry's top manufacturers of firefighting equipment. Ferrara was also the largest sales and service center in the South for automobile extrication equipment, with Chris being a well known and sought after extrication instructor.

Ferrara Firefighting Equipment was incorporated in 1982. At that time, Chris established a full-scale service, warranty, and repair center for several major apparatus manufacturers. This service center offered preventative maintenance and repair on existing apparatus and warranty service repairs on new vehicles.

Early in 1988, Ferrara Firefighting Equipment expanded and began offering major refurbishment of apparatus and assembly of pre-built fire bodies and fire pumps on new and used chassis. Later that same year, with the desire to meet the individual needs of his customers, Chris started Ferrara Fire Apparatus, a separate company from his successful equipment business.

This new company manufactured heavy duty commercial pumpers, tankers, mini pumpers, and service/utility vehicles. This marked the beginning of an extensive line of fire, rescue, and specialty vehicles. While Ferrara's focus changed from that of a distributor and service provider to a nationwide manufacturer of fire and emergency vehicles, the principles of serving the needs of individual fire departments did not change. By 1992, Ferrara Fire Apparatus was ranked as the tenth largest U.S. manufacturer of fire apparatus, delivering over one hundred heavy duty, custom fire apparatus.

Ferrara's now famous heavy duty, extruded aluminum fire body was introduced in 1992. Constructed entirely of aluminum plate and extrusions, this innovative concept led the industry with its engineering and design. The introduction of the extruded aluminum body, used for pumpers, tankers, rescues and, eventually aerials, greatly expanded the product line. Now Ferrara was the only fire apparatus manufacturer in the industry to offer its customers such a wide variety of custom fire body styles and materials, from galvanneal steel, aluminum, and stainless steel modular and unitized all-welded bodies, to Ferrara's innovative new extruded aluminum design.

Understanding that no two fires are identical and no two fire departments are exactly alike, Ferrara was determined to offer market driven concepts to the fire service. Ferrara once again expanded its offering of fire apparatus to include a full line of aerial devices. Ferrara's custom designed fire apparatus now included pumpers, tankers, hazmat units, large and small rescue vehicles, as well as aerial ladders and platforms.

In 1994, Ferrara designed and built a new facility located in Holden, Louisiana, a 110,000 square foot, state-of-the-art manufacturing facility, located between Baton Rouge and New Orleans. The facility, designed around actual stages of production, remains one of the most modern in the industry and incorporates the latest in technology and equipment.

In 1998 Ferrara Fire Apparatus introduced its premium custom fire chassis, the Inferno. The Inferno was recognized for its innovation and automotive quality design, offering a roomier and more comfortable cab. The chassis was easier to handle under the most demanding situations. Inferno innovations included heavy duty roll cage cab framework, all 3/16" thick marine grade aluminum cab skin, oversized windshield and side windows for improved driver visibility, certified and optimized steering for improved handling, oversized air conditioning systems for better climate control, and attention to detail safety and maintenance.

Introduced shortly thereafter was the Igniter, a mid-range custom chassis designed with the same quality and safety features of the Inferno. Soon to follow was the Inferno Lo Cab for low profile aerials, a 2-door rescue cab and a 4x4 all wheel drive chassis, all built for use in extreme conditions. Other Ferrara innovations followed, including Independent Extreme Duty all aluminum interior, Independent Front Suspension, Smart Wheel steering wheel and CAP, the Complete Airbag Protection system that was the industry's first system to provide airbag protection for all outboard-seated passengers and seat belt draw-down protection for all occupants.

The Inferno and Igniter cab has successfully passed ECE-29 crash worthiness testing. The vertical load achieved was 65,979 pounds, or approximately 300% of the total required by the ECE. The frontal impact was 3,726 pounds, or 1-1/4 times the ECE standard. Ferrara went a step beyond that required by the standard by also conducting vertical load testing with the same 66,000 pound weight, resting it atop their heavy duty extruded aluminum fire body. Ferrara is the only fire apparatus manufacturer who has tested their cab and body to these stringent standards.

To meet growing interest in the Inferno and Igniter custom chassis, Ferrara Fire Apparatus, expanded again in 2000 by adding a 40,000 chassis manufacturing facility and a 35,000 square foot used apparatus center. This increased Ferrara's manufacturing and service facilities to 185,000 square feet. In 2005 an additional 10,000 square foot plant expansion was completed to make way for additional chassis production as well as an increasing service, repair and refurbishment business.

Some of the many Ferrara, benchmarks include the Spirit of Louisiana fire truck that was donated by the citizens of Louisiana, and manufactured by Ferrara Inc., to exact FDNY specifications, marked the first new fire apparatus to be built and donated to the City of New York after September 11.

Ferrara introduced the Strong Arm, a revolutionary firefighting vehicle at Fire Rescue International in New Orleans in 2004. This vehicle is a multi-purpose fire and rescue vehicle that boasts water flow of 1500 GPM and lifting capacity of 1,800 to 10,000 pounds.

That same year, Ferrara introduced the Inundator industrial fire apparatus. Designed for the high volume water flows required for use in industrial firefighting, the Inundator can achieve an industrial or municipal rating of 3000 GPM. Flows of 5000 GPM or greater are achieved by this impressive industrial pumper apparatus when it is supplied by a pressurized water source.

In 2005, Ferrara expanded its manufacturing facility once again. It added capacity to the body manufacturing facility, tied the chassis and body plants into a single facility and started a dedicated repair and service facility. With nearly 300,000 square feet of manufacturing capacity, Ferrara is one of the largest fire apparatus manufacturers in America. The repair and refurb center operates out of 14 bays in a separate facility. They skillfully perform everything from minor repairs to major collision repair and body/cab replacements.

Ferrara expanded again in 2009 with 2 new additions to its Holden manufacturing facility. Added was an on-site tilt table test center, giving Ferrara the ability to meet new NFPA 1901 tilt table testing requirements. Also, to meet the growing demands of its industrial fire apparatus market, a new pump test area was constructed. This facility is in addition to Ferrara's 45,000 gallon, two-truck UL pump test center and accommodates the substantially larger water flows required of fire apparatus designed for petrochemical plants, refineries and other industrial fire apparatus facilities.

The corporation’s commitment to top quality, premium service and outstanding performance at an affordable price has been the trademark of Ferrara Fire Apparatus, directly contributing to the success and reputation the company is fortunate to enjoy in the fire service industry.

Ferrara Fire Apparatus considers the customer to be a very valuable asset. By listening to them they are able to devise many of the innovative ideas that soon become industry standards. Service after the sale, a mainstay of Ferrara, prompted the manufacturer to be the first in the nation to provide fire departments with a 24-hour emergency hotline for warranty and service.

All Ferrara products are designed to be easy to use, easy to service, and tough enough to be dependable for many years. Additionally, their knowledgeable and experienced sales and dealer network spans across the United States and the globe with professional sales and skilled service centers throughout.

The future looks very bright for Ferrara Fire Apparatus and its fine craftsmen. The company's philosophy, Leading the Way, leaves no reason for doubt that Ferrara will play a major role in the future of the fire apparatus industry. Today, Ferrara Fire Apparatus, consistently ranks in the nation's top five fire truck manufacturers, delivering several hundred custom and commercial fire trucks annually.